Prioritising Safety, Security, and Productivity in Oil and Gas Operations

Safety, Security, SOP and Quality are four non-negotiable parameters in the Oil and Gas industry and in parallel the Production should go unhampered.

Given this unparalleled challenge, we have delivered and witnessed Camera AI playing a critical role in ensuring the parameters are adhered too. Each of the locations in Oil and Gas industry have traditional CCTV installed and the Camera AI in non-intrusive layer on top of this which detections and instantaneously notifies non-compliances for speedy action. And also deliver analytics using which turn around efficiency, optimal utilization of infrastructure and operational efficiency can be measured. Measuring these key analytics helps manage the productivity and enhance it.

Features and Benefits

Comprehensive Coverage

Our Camera AI solution successfully deployed in more than 100+ locations within the Oil and Gas industry, ensuring no blind spots.

Enhanced Security

With an average of 30 cameras at each location, we guarantee heightened security and surveillance capabilities.

User-Friendly Dashboard

Our intuitive dashboard is accessible to multiple users at every location, making monitoring & management a breeze.

Instant Notifications

Stay informed with email and WhatsApp notifications, ensuring that non-compliances are swiftly addressed, promoting safety & compliance.

Seamless Integration

We seamlessly integrate with multiple downstream systems at each location, streamlining your existing infrastructure.

Operational Efficiency

Measure turnaround efficiency, optimise infrastructure, and enhance operational efficiency using our analytics, boosting productivity and cost-effectiveness.

Compliance Assurance

Our Camera AI ensures adherence to safety, security, SOP, and quality standards, safeguarding your operations.

How it Works?

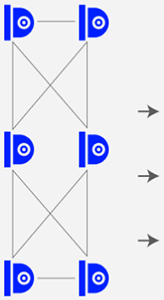

ZestIOT Camera AI Engine

Use Cases

ZestIOT’s Advanced Video Analytics is applied to enhance safety, security, and operational efficiency across LPG and Lube Locations within a plant. This technology can lead to cost savings, improved compliance, and better overall management of plant operations. Some of the use cases it serves are :

Real-Time Alerts for Non-compliance Monitoring

Detect and alert authorities in real-time when safety or compliance violations occur at LPG and Lube Locations, such as unauthorised personnel entry or improper handling of materials.

Bay Utilisation and Turnaround Monitoring

Analyse and optimise the utilisation of bays within the plant for various activities, ensuring efficient allocation and turnaround times for each task.

Operational Efficiency Tracking for Packed Trucks and Bulk Trucks

Monitor and report the operational efficiency of packed and bulk trucks, including loading/unloading times, route adherence, and vehicle maintenance requirements.

Integration with Planning Module

Seamlessly integrate video analytics data with the planning module to improve end-to-end supply chain visibility and tracking of cylinders from production to delivery.

Operational Efficiency Tracking for Packed Trucks and Bulk Trucks

Monitor and report the operational efficiency of packed and bulk trucks, including loading/unloading times, route adherence, and vehicle maintenance requirements.

Integration with Planning Module

Cylinder Count and Defect Identification

Automatically count cylinders and identify defects during filling and maintenance processes, reducing manual inspection efforts and improving product quality.

SOP Compliance during Filling and Maintenance

Safety and Security Surveillance

Continuously monitor the perimeter and interior of the licensed area for security breaches, safety hazards, or suspicious activities, and trigger immediate alerts to security personnel.

Automation of Bay Operations

Automate bay allocation, scheduling, and monitoring, improving the efficiency of loading, unloading, and other activities conducted at the bays.

Safety and Security Surveillance

Automation of Bay Operations

Automate bay allocation, scheduling, and monitoring, improving the efficiency of loading, unloading, and other activities conducted at the bays.

Automation of Gate Operations

Automate the entry and exit processes at the plant’s gates, including vehicle identification, access control, and documentation, enhancing security and efficiency

Automation of Weighbridge Operations

Streamline the weighing process for incoming and outgoing trucks, ensuring accurate measurements and reducing waiting times.

All the above features come with configurable dashboard enabling Predictive Analysis and Control

~80

Cameras per Location

Users per Location

Downstream Systems

Email and WhatsApp notifications enabled to all users

Trusted By

Case Studies

Revolutionizing LPG Cylinder Distribution with AI-Driven Automation

The Client: Oil and Natural Gas PSU with a Nationwide LPG Distribution Network

Revolutionizing LPG Cylinder Distribution with AI-Driven Automation

The Client: Oil and Natural Gas PSU with a Nationwide LPG Distribution Network